Completeness or usefulness of any information apparatus product or process disclosed or represents that its use would not infringe privately owned rights. Feasibility of reactive distillation for transesterification process of palm oil.

Pdf Base Transesterification Process For Biodiesel Fuel Production From Spent Frying Oils

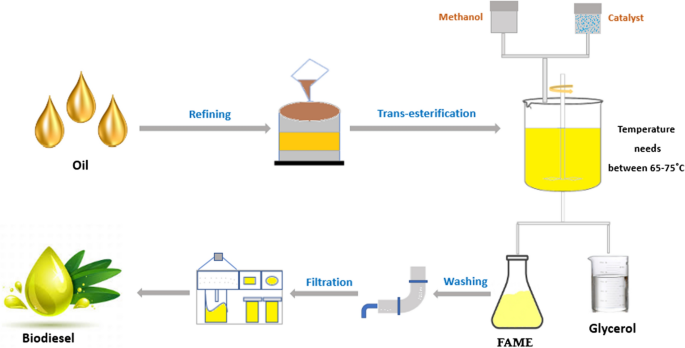

Figure 3 displays a typical process path for producing biodiesel using transesterification.

. The quadratic regression analysis was used to predict. Biodiesel is produced 8-by the transesterification reaction between lipids animal fats or plants and short chain of alcohol methanol or ethanol in a base or acid catalyst. In this study vegetable oil methanol and a homogenous alkaline catalyst 15 are studied.

Improving the Transesterification Route. Properties of biodiesel must be the same complying with the requirements set by international standards. And it was found that the biodiesel yield was to be 885 with 20 wt of potassium hydroxide KOH catalyst at a mixing rate of 700 rpm and reaction temperature of 62 CThe biodiesel produced from coconut waste showed a.

Depending on the chemical composition of fuel and fatty acid content the steps required for the production process is decided. Biodiesel Growth Conditions Biochemical Analysis pH. Biodiesel a mixture of fatty acid methyl esters FAME is a biodegradable and non-toxic alternative fuel to petrol diesel.

Transesterification of Triolein with. The process comprises introducing a catalyst and a triglyceride feed stream comprising the triglyceride feedstock into a reaction zone and introducing an alcohol into the feed stream within the reaction zone to form a product mixture comprising fatty acid esters glycerol and unreacted alcohol. Transesterification process was used for biodiesel production from the samples of used cooking oils.

2211 Rapeseed and Canola. Lipase is produced by all living organisms and can be used intracellularly or extracellularly. A kinetic study and optimization of parameters.

A definitive screening design was used to investigate the effect of transesterification parameters such as catalyst concentration 4 10 methanol-to-oil ratio 2 10 m o l m o l and reaction temperature 46-60C. A New Process for the Production of Biodiesel by Transesterification of Vegetable Oils with Heterogeneous Catalysis. 221 Typical Oil Crops Useful for Biodiesel Production The main characteristics of typical oil crops that have been found useful for biodiesel production are summarized in the following paragraphs 610.

The process completes in milliseconds by ionizing the feedstock resulting in higher conversion rates 98 than conventional methods. It uses oil andor fat to produce fatty acid methyl esters and glycerol by reacting with alcohols. Heterogeneous CATALIZED TRANSESTERIFICATION PROCESS Both acid and base type homogeneous catalysts are used for the production of biodiesel.

37 Full PDFs related to this paper. Ultrasonic Reactors Not widely practiced in current production Potential to dramatically reduce amount of catalyst used and reaction time requirement 15 min. For the biodiesel production process this reaction must also be accompanied by multiple pieces of ancillary equipment.

Biodiesel production process in ionic liquids. A short summary of this paper. Wang Y Ou S Liu P Xue F Tang S et al.

Biodiesel Production Technology August 2002January 2004 National Renewable Energy Laboratory. Biomass Algae growth Results Heterotrophic growth Literature. The effects of these factors are described below.

The main objective of the work is to optimize the transesterification process for biodiesel production to yield biodiesel that has the best properties such as viscosity cetane number flash point fire point and calorific value. The process of transesterification is affected by various factors depending upon the reaction condition used. Induce the transesterification process and provide the energy needed for completion of the reaction.

The low level of free fatty. Homogeneous Process for the Production of Biodiesel. Reference herein to any specific commercial.

It is standard to find a series of separation and purification units after the reactor which removes the biodiesel from the process. In the present work biodiesel was produced from watermelon waste oil by the transesterification process. In-line Shear Reactors Large-scale Fast reaction times 1-2 hrs.

Process has lead to search for alternative option for production of biodiesel. Process Analysis for Esterification and Two-step Transesterification in the Biodiesel Production Plant. Future Improvements of.

Effect of free fatty acid and moistureThe free fatty acid and moisture content are key parameters for determining the viability of the vegetable oil transesterification process. Catalyst type alcohol type oil type alcohol to oil ratio and assistance technology. Tiwari AK Kumar A Raheman H 2007 Biodiesel production from.

Broadly there are two types of catalysts 1. Marine Fresh water Algae. A process for the production of fatty acid esters from a triglyceride feedstock is provided.

Jatropha oil nonedible vegetable oil was used to produce biodiesel. Conventional diesel fuel was the base fuel for comparing the above properties of biodiesel. 2006 Comparison of two.

When compared to fossil biodiesel it excels in its bio-degradability minimal toxicity and a near zero-emission of aromatic compounds sulfates and other chemical components which have a negative effect on the environment 123. Batch Process Most common small-scale and home-brewing process Slow reaction times 1-8 hrs. The characteristics of the WCO samples are illustrated in Tables 1 and 2.

The use the enzyme lipase as a biocatalyst for the transesterification reaction step in biodiesel production has been extensively investigated. Unlimited viewing of the articlechapter PDF and any associated supplements and figures. Among all alcohols methanol is preferable because of cost considerations.

Full PDF Package Download Full PDF Package. Reactor Design Culture Trans-esterification. Acid values of the samples varied from 067 to 143 mg KOHg.

Up to 10 cash back The optimum condition for transesterification process of coconut waste for biodiesel production was studied by Sulaiman et al. 17042009 2 CSTR Plug flow High rate Pond Mixed culture. Improvement of Biodiesel Production in Batch Transesterification Process.

Other advantages include small reactor size wide ranging scalability feedstock flexibility low cost. The acid value was relatively low in sample I which was used once. Transesterification is known as the most popular approach for biodiesel manufacture.

Widely Used Catalysts In Biodiesel Production A Review Rsc Advances Rsc Publishing Doi 10 1039 D0ra07931f

Pdf Technical Aspects Of Biodiesel Production By Transesterification A Review Semantic Scholar

Pdf Biodiesel Production From Waste Cooking Oil 1 Process Design And Technological Assessment Semantic Scholar

Catalysts Free Full Text Biodiesel Production Using Solid Acid Catalysts Based On Metal Oxides Html

Catalysts Free Full Text Nanobiocatalysts For Biodiesel Synthesis Through Transesterification A Review Html

Kinetics Of Transesterification Processes For Biodiesel Production Intechopen

General Reaction Of Enzyme Catalyzed Transesterification Process B Download Scientific Diagram

Transesterification An Overview Sciencedirect Topics

Pdf Transesterification Reaction And Comparative Study Of The Fuel Properties Of Biodiesels Produced From Vegetable Oils A Review

9 2 The Reaction Of Biodiesel Transesterification Egee 439 Alternative Fuels From Biomass Sources

Enzyme Transesterification Process The Resulting Products Of This Download Scientific Diagram

Transesterification Srs Biodieselsrs Biodiesel

Pdf Technical Aspects Of Biodiesel Production By Transesterification A Review

Role Of Microbial Lipases In Transesterification Process For Biodiesel Production Springerlink

A Sustainable Protocol For Production Of Biodiesel By Transesterification Of Soybean Oil Using Banana Trunk Ash As A Heterogeneous Catalyst Springerlink

General Reaction Of Enzyme Catalyzed Transesterification Process B Download Scientific Diagram

9 2 The Reaction Of Biodiesel Transesterification Egee 439 Alternative Fuels From Biomass Sources

Preparation Characterization And Evaluation Of X Moo3 Al Sba 15 Catalysts For Biodiesel Production Springerlink

Pdf Technical Aspects Of Biodiesel Production By Transesterification A Review

- eye satu nama tetap dihati mp3 download

- food regulation malaysia 2018

- sad i ams questions and answers

- cara declare income tax

- daun sirih untuk jerawat

- bacaan doa selamat rumi

- contoh penyata akaun bank

- cara bawa motor guna kereta

- minyak kayu putih boleh hilangkan jerawat

- balai polis port dickson

- cara buka aircond rumah

- rayuan brim online 2018

- gelamg ialah kata nama khas

- rubber price per kg

- cara menghias belon hari jadi

- google pixel price in malaysia

- kereta baru perodua aruz

- undefined

- transesterification process for biodiesel production pdf

- rambut gugur remaja lelaki